How Automatic Fire Suppression Protects Green Energy

The events of the past year have placed climate change and green energy under a brighter spotlight than ever before. Extreme weather across the world coupled with severe energy supply issues mean the world needs abundant green energy like never before.

The consensus surrounding this issue is almost uniquely strong, with the scientific community, global governments, businesses, and consumers all broadly agreeing that more needs to be done to create a sustainable future for our planet.

The only problem lies in how this vision can be turned into reality. It is clear that green energy generation must become safer and more cost-effective than it currently is to encourage more widespread adoption across the world. Preventing costly damage to wind turbines, solar panels, and other renewable energy generation systems is a key plank of this strategy.

Renewable energy needs reliable protection

As with any electrical system, every renewable energy generation system is at risk of fire. The three most common methods of green energy generation are photovoltaic (solar power) panels, wind turbines, and hydroelectric power (generated by the movement of water). All of these systems contain many sensitive components alongside converter cabinets, capacitor cabinets, and transformers that work together to convert the energy generated into electricity and adjust the voltage of this electricity.

Usually, these components work together to ensure electricity is safely delivered to the power grid. However, they can also act as ignition points where a fire can easily break out if the right (or rather, the wrong) combination of heat, fuel, and oxygen is present.

The value of the damage caused by a fire in a generator system can vary wildly depending on a number of factors, but it can easily total into the millions. The average cost of a wind turbine is estimated to be between $4m-$8m USD, according to insurers. In some cases, these fires can pose a significant risk to human life, such as in the case of the 2020 Srisailam dam fire in India, where a control panel short circuit in the underground facility caused a blaze to break out.

These incidents will only become more common as green energy generators proliferate. The BRE National Solar Centre study, carried out on behalf of the UK government, found that, while fires in photovoltaic systems were relatively rare, the total number of incidents did increase proportionally in line with the number of systems installed. As large solar farms get even larger and the number of domestic and commercial properties with solar panels also grows, this means the risk of fire grows at the same rate.

Likewise, as the number of offshore and onshore wind turbines continues to increase across the globe, so too does the number of fire incidents. Fire is the second most common cause of catastrophic wind turbine failure (only behind blade failure), according to research from Imperial College London. The most common cause of wind turbine fires is from an electrical fault – such as overloading, arcing, or cable failure – but they can be caused by poor maintenance and even lightning strikes.

How does an automatic fire suppression system help?

When it comes to suppressing any fire, every second counts. However, green energy generators – particularly wind turbines, which tend to be located as remotely as possible – cannot rely on manual fire suppression to deal with a blaze in the short window before it gets out of control. 91% of wind turbine fires are not reported at all according to the International Association for Fire Safety Science (IAFSS), much less actively extinguished.

Automatic fire suppression systems are the obvious solution to this problem. These systems can automatically detect a fire and deploy the suppression system to fight it at the point of ignition. This means the fire never gets the chance to spread out of control. However, automatic fire suppression is not a one-size-fits-all solution. Each installation has its own unique considerations and requirements.

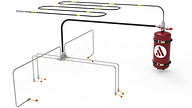

Indirect Ardent Fire Suppression System

Direct Ardent Fire Suppression System

At Ardent, we manufacture two different automatic systems for static equipment. The first is a pneumatic system. These systems utilise pressurised tube routed around all identifiedfire hazards in a cabinet to detect and deliver their suppression agent. When a fire ignites, the heat melts the tube, creating a rupture. This rupture causes the suppression agent to be deployed directly onto the cause of the fire.

While this system has many uses, it is not a universal solution. By its very nature, a pneumatic system is designed to rupture. This can lead to false discharge issues in areas with heavy or constant vibration, such as a wind turbine nacelle brake, creating unnecessary downtime and even causing damage to the system.

This lack of reliability in difficult conditions does not give green energy systems the solid foundations they need to operate safely.

To rectify this issue, we use a different detection technology known as the linear heat detection (LHD) cable. This cable is routed around all potential fire hazards much like the pneumatic system, however, instead of using a pressurised tube, it uses copper wires coated in a heat-sensitive polymer. Once the heat from a fire melts this polymer, the two wires contact and cause a short circuit that signals a control module to deploy the suppression system. This allows the LHD cable to differentiate between damage caused by fire and kinked or cut cabling. As a result, it will only deploy the fire suppression agent in the event of a fire.

Depending on the nature of the equipment being protected, either a pneumatic or an LHD system may be preferred. However, when specifying the fire suppression system, consideration must also be given to the choice of suppression agent. And, when dealing with electrical cabinets and sealed panels, one choice stands out above the others.

Gaseous suppression – a clean agent for clean energy

The end goal of suppressing fires on renewable energy generators is to protect expensive assets. By doing so, downtime is minimised and the impact on power generation is lower.

Automatic fire suppression systems are beneficial as they can deploy before the fire has the chance to spread. However, using the wrong suppression agent can, in some cases, cause almost as much damage and downtime as the fire itself. When dealing with wind turbines or advanced photovoltaic systems, this avoidable damage comes at a high cost.

In the interest of avoiding expensive repairs and extensive downtime at a time when the world relies on each wind turbine, solar panel, and hydro system more than ever, a clean gaseous suppression agent is the optimal solution. These systems use a non-corrosive, non-conductive gas to starve a fire of oxygen and smother it before it can spread. As its ‘clean’ moniker suggests, the gas disperses quickly and leaves behind no residues, making it quicker and easier to make necessary repairs and get the affected electrical system back into operation.

As a fast-deploying solution that causes no collateral damage, the clean agent fire suppression system has an enormous role to play in protecting the green energy assets of the future. If the global reliance on these assets continues to grow, it must be supported by improved safety systems.

Only then will renewable energy generation have a secure foundation to build upon.

To learn more about Ardent’s safety and asset protection systems, contact us today.